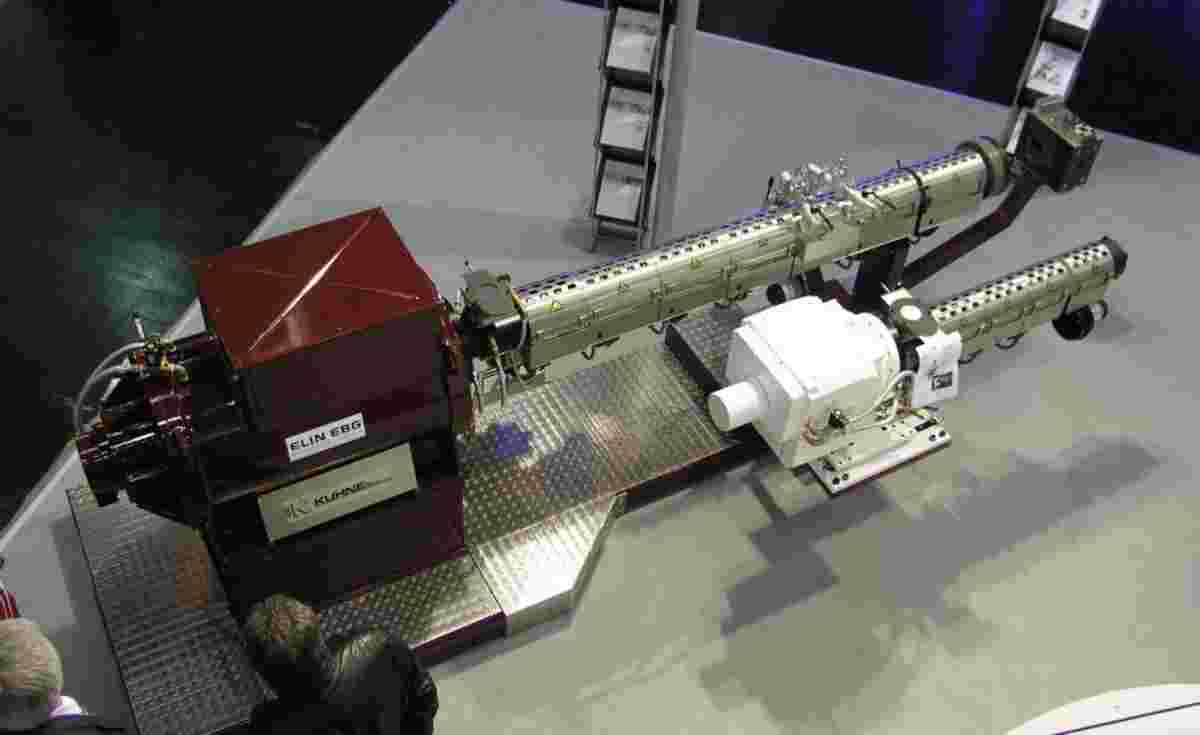

The focus of development is on single-screw extruders, which are built in sizes with screw diameters ranging from 25 mm to 250 mm and lengths, in each case based on the diameter, of 20 D, 24 D, 30 D, 33 D, through 36 and 39D to the special size of 45 D.

All extruder sizes are available with or without venting, venting possible in double or even quadruple execution.

Modern screw geometries ensure pressure constancy, good homogenization and highest output values. In addition to plastics, KUHNE extruders are also used for processing biodegradable materials, wood flour-filled or glass fiber-reinforced plastics, and other extrudable materials.

On average, more than 200 extruders leave our plant in Sankt Augustin every year. In addition to customized extruders, KUHNE builds certain machine types in series to ensure short delivery times at a favorable price/performance ratio.

KUHNE single screw extruder - The product features

- Screw diameter from 25mm to 250mm

- barrel length 24 to 45D (with and without venting)

- High Speed Extruder 60mm, 72mm and 90mm screw diameter, screw speed up to 1.500 rpm, output rates up to 2.500kg/h PS, 2.100kg/h PP. Also suitable for ABS, with low energy input.

- Water-cooled, low-noise motors with direct drive.

- 3-zone screws, venting screws, barrier screws with shearing and mixing section.

- Barrier screws for processing polyolefins without screw changeover

- Screw discharge optionally to the front or to the rear

- Single venting, double venting and quadruple venting (for hygroscopic polymers)

- Water-cooled drive technology with highest efficiencies as asynchronous, synchronous and torque motors